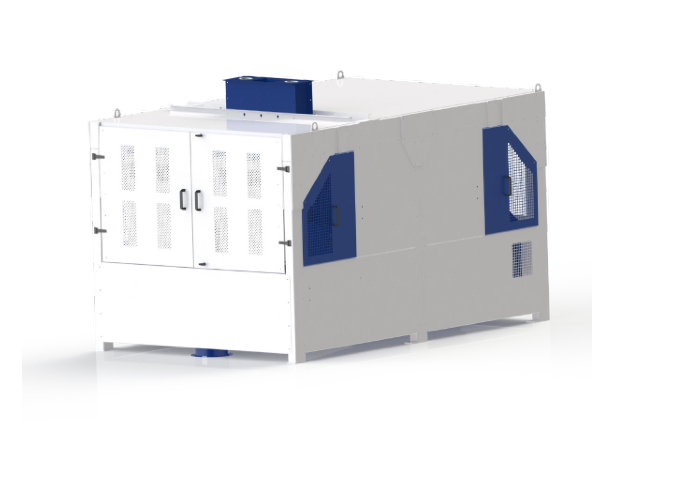

Sifters

APPLICATION

Schneider Jaquet sifters are designed for multiple uses and meet many different needs in terms of sifting or specific product separation.

Schneider Jaquet sifters can separate products in 2 to 4 sizes (gradings) and are already used in the following applications:

• Saw dust

• Soy bean flour

• Cattle feed flour

OPERATION

Schneider Jaquet sifters operate on the basis of planetary movement, allowing better distribution of grains all over the sifting surface and thus enhancing the flow rate and yield.

Compared with Schneider Jaquet cleaners, sifters have 3-metre long screens and a gentler slope, allowing longer cycles on the sifting surface.

ADVANTAGES

• High quality and enhanced flow rate

• Gentle slope (5°) over 3 metres for specific applications

• Unblinding of sifts is achieved with de-gumming balls

• Heavy-duty, reliable equipment

• Easy maintenance

• Low maintenance costs

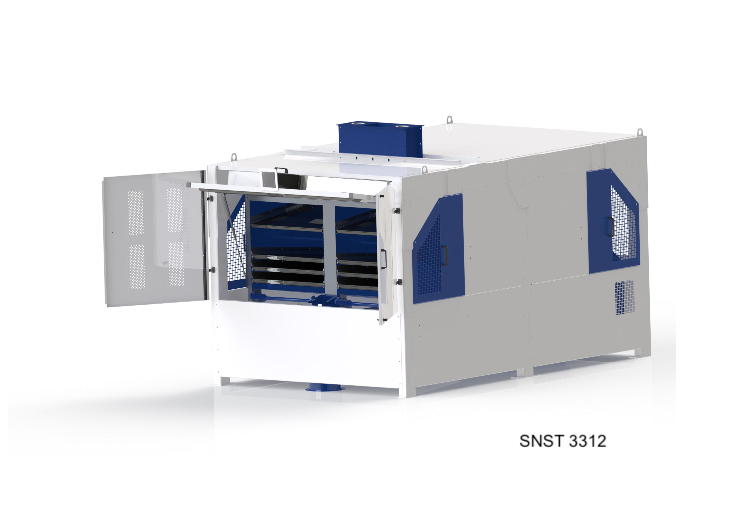

• Short screen changing time

• Wide range of sift perforation sizes down to 200 µm

| Models | Surface area of screens (sq. m.) | Number of size gradings | Dimensions** (mm) | Weight** (kg) | Power (kw) | ||

| Length | Width | Height | |||||

| SNST 106 | 6 | 2 | 3,528 | 2,364 | 2.282 | 2,750 | 3 |

| SNST 112 | 12 | 2 | 3,539 | 2,459 | 2.717 | 2,350 | 3 |

| SNST 212 | 12 | 3 | 3,851 | 2,568 | 2.282 | 2,550 | 3 |

| SNST 224 |

24 | 3 | 3,729 | 2,575 | 3.377 | 4,000 | 4 |

| NST 1133 | 9 | 4 | 3,916 | 1,648 | 1.882 | 2,500 | 1.5 |

| NST 2133 | 18 | 4 | 4,214 | 2,364 | 2.317 | 3,800 | 3 |

| SNST 3312 | 18 | 5 | 4, 214 | 2, 364 | 2, 317 | 3, 800 | 3 |

** Weight and dimensions of standard machines